WHAT WE DO

Extrusiones Vinilicas Aragonesas, S.L. (ARAEXfilm), was created on March 1, 2015, after the purchase of EXTRUSION DE RESINAS VINILICAS, S.A. (ERVISA), a pioneering company in the manufacture by extrusion of PVC and polyolefin shrink film.

ERVISA, which was founded in 1979 as a manufacturer and processor of plastic products, in 2014 had two production centers (one in Zaragoza and other in Asturias) that allowed to produce a wide range of products.

ARAEXfilm, after the purchase of the production center of Zaragoza, is dedicated to the manufacture of the same products that till those moments ERVISA manufactured and some other products have been incorporated as the result of the new designs applied

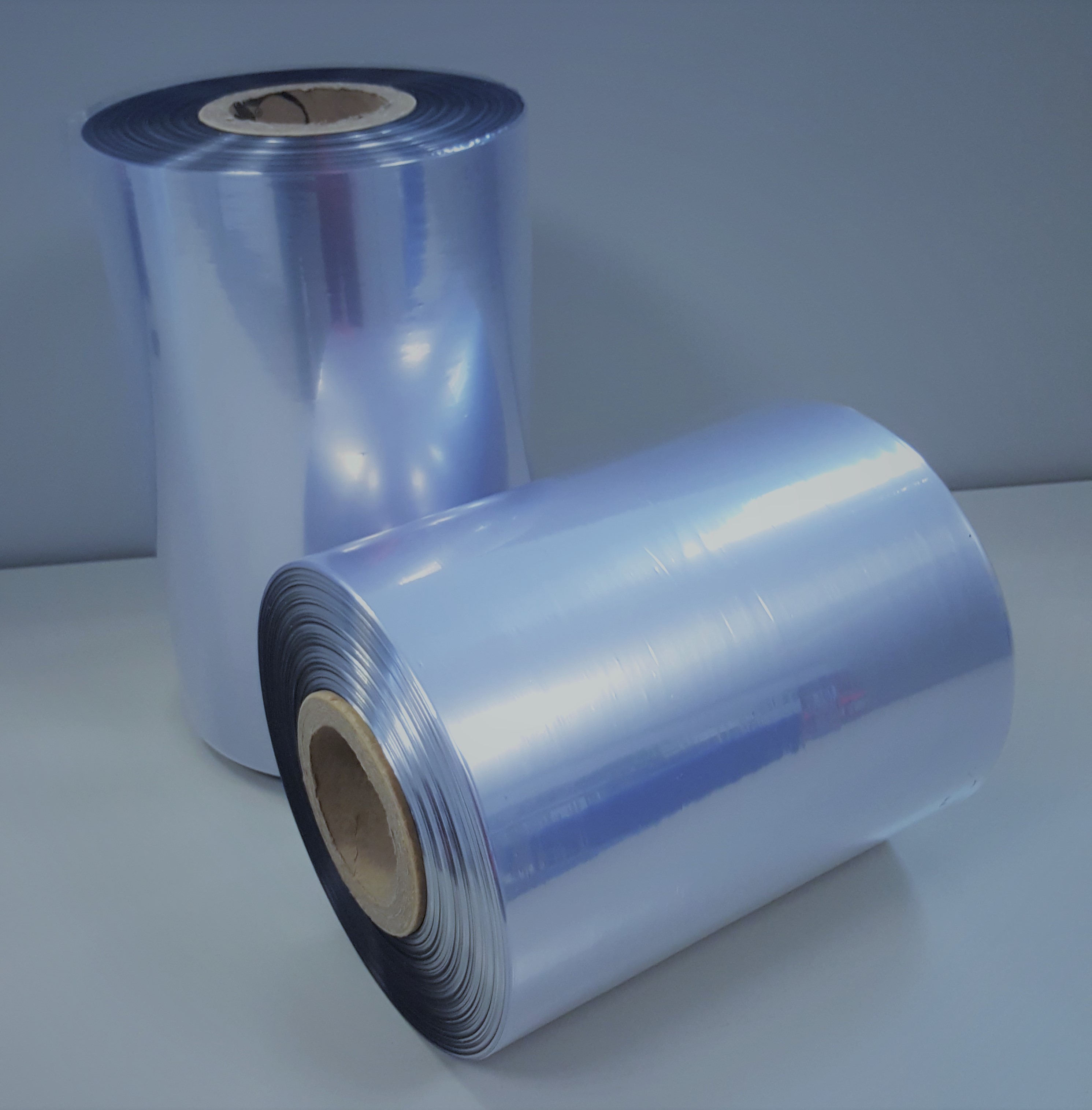

The families of the products manufactured by ARAEXfilm are as follows:

- FILMS DERIVED FROM PVC: Shrink and rigid films

- FILMS DERIVED FROM POLYETHYLENE: Shrink polyolefin films made with the double bubble, multilayer system.

From August 2018, we have begun too the manufacture of polystyrene products.

New products manufactured by ARAEXfilm:

• FILMS DERIVATED FROM POLYSTYRENE: Polystyrene bioriented antistatic films transparent or opaque manufactured by blow extrusion.

The activity of Araexfilm is directed towards the manufacture of plastic film from resins/pellets of polymer materials (mainly derived from the polychloride of vinyl, from the polyethylene and polystyrene) that have a great variety of uses in different fields.

The differences in terms of composition, as much for the material, as for additives (materials that favour the slide, the seal, the thermal resistance, the optical properties, etc.) originate for themselves a wide range of products. Nevertheless, we must not forget that this offer brings to diversify in many major measures due to the wide range of possibilities that they present as soon as the composition is well defined:

On one side, by regulating the thickness of the film, it is possible to make different thicknesses for each product, in the case of polyvinyl chloride usually between 15 and 35 microns with two predetermined standard values (23 and 30 microns), and in the case of polyethylene normally between 11 and 25 microns, and the values more common for polystyrene are between 50 and 70 microns.

On the other hand, the film is wound on the cardboard core in the length and width desired by the customer, here being the possibilities almost infinite; However, although in this phase the flexibility is enormous, it is often used to standardized dimensions for both the width and the length of the rolls, so we have created a stock for immediate service.

ARAEXfilm stands our for developing tailored products according to the customer needs that respond to individual and specific requirements for each application